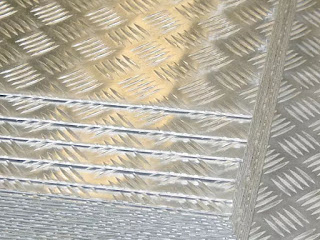

Aluminium Sheet Supplier in UAE

At DINCO Trading

LLC we stock Aluminium Sheets / Plates in various alloys with a variety of

mechanical and chemical qualities to meet our customers' needs. We are the top Aluminium

sheet supplier that will consider your

requirements prior to customizing the inventory. Aluminium alloy 1100 sheets

are made of 99% pure aluminium and are the most regularly used aluminium alloy

in the UAE for conventional sheet metal applications. Aluminium alloy 3003 is a

medium-strength alloy with excellent corrosion resistance, making it

appropriate for use in protective jackets. The bendability of Aluminium Alloy

5052 makes it an excellent choice for outdoor applications. Aluminium alloy

5083, which is resistant to seawater corrosion, is utilized in marine and other

offshore applications. Aluminium Alloy 6082 is a high-strength alloy that is

utilized in structural and machining applications.

Aluminium

Alloy 1100

Aluminium alloy

1100, often known as commercial grade aluminium, is a nearly pure form of

metal. It is 99% aluminium, with no more than 1% manganese, copper, silicon, or

zinc mixed in for added strength. This form of commercially pure aluminium has

exceptional welding properties. Because of its superior forming capabilities in

annealed stages, 1100 is the most often used aluminium alloy.

Aluminium Alloy 3003

The HINDALCO-INDIA

AA 3003 sheets we have are authentic Hindalco

Aluminium Sheets, and all genuine HINDALCO sheets have Ink

Stencil Marks on individual sheets displaying Mill name, Alloy Temper, and so

forth. If required, we give mill test certifications with matching coil/heat

numbers under ASTM standards with all of our deliveries.

Aluminium

Alloy 5005

Anodized Quality

Aluminium Alloy Sheets in 5005 is a logical choice for architectural

applications, flashings, and curtain walls, among other things. The 5005 AQ

alloy is made anodized for a decorative architectural finish.

Aluminium

Alloy 5052

This aluminium

alloy has high corrosion resistance. Because it is non-heat treatable,

Aluminium Alloy 5052 is noted for its excellent corrosion resistance. Aluminium

is generally alloyed with elements to improve material qualities. When it comes

to distinguishing one alloy from another, the amount of alloy used counts a

lot. The aluminium alloy 5052 has 97.25% aluminium, 0.25% copper, and 2.5%

magnesium.

Aluminium

Alloy 5083

AA 5083, a high

magnesium alloy containing traces of manganese and chromium, is well-known for

its outstanding performance in harsh situations. Both seawater and industrial

chemical conditions have little effect on AA 5083. After welding, AA 5083

maintains its excellent strength. AA 5083 is utilized in the shipbuilding

sector due to its strength and corrosion resistance. Marine applications,

pressure vessels, drilling rigs, transportation equipment, and TV/Communication

Towers are just a few areas suitable.

Aluminium

Alloy 6082

If you're seeking

for highest alloy in the 6000 series, aluminium alloy 6082 is a solid choice. A

structural alloy is what it's called. The alloy 6082 is used in machine

processing. It's a relatively new alloy that's also the strongest. In many

applications, the aluminium alloy 6082 has taken the place of the alloy 6061.

Roof trusses, milk churns, cranes, ore skips, bridges, and highly strained

applications are just a few of the uses for aluminium alloy 6082. This alloy is

mostly used in high-stress situations.

Aluminium

Alloy 7075

Aluminium alloy

7075 is a high-strength aluminium alloy that can equal the strength of many

sheets of steel while conserving weight. Aluminium, Zinc, Magnesium, and Copper

are alloyed together to make 7075. This alloy is commonly used in tool moulds,

bike frames, and other sports equipment because of its strength. Alloy 7075 is

also widely utilized in the aerospace and automotive sectors.

Comments

Post a Comment